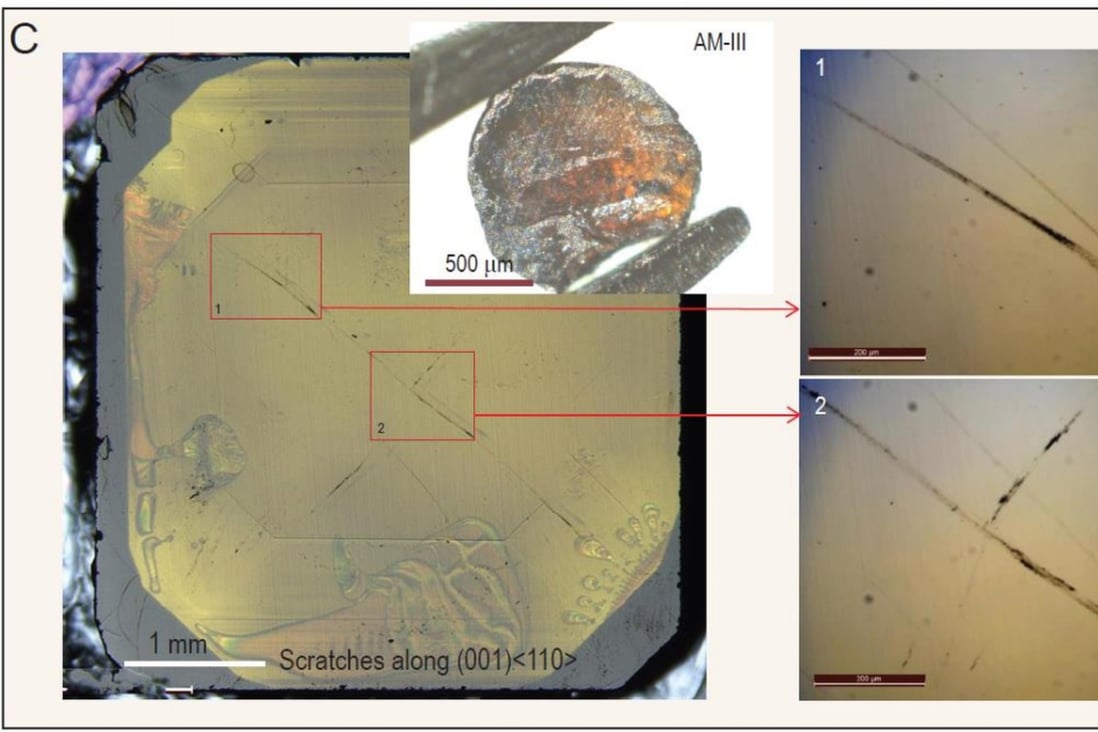

Researchers from China developed the world’s strongest glass. AM-III, a glass so hard that it can easily scratch diamond crystals. Read to know all about its development and applications.

What is AM-III?

AM-II is a transparent material that can be produced in various sizes. It is made up of ‘fullerenes’ i.e., carbon atoms that are arranged in a hollow football-like system. And among the combinations used by the researchers, this combination was the strongest. Wondering how they did that? Well, they crushed and blended fullerenes before applying intense pressure and heat (25GPa and 1,200°C) for 12 hours inside a chamber. Then they spent the same amount of time cooling the material down.

They could have made the material stronger by increasing pressure and temperature, right? Nope, doing that would kill all its ‘special properties’. Moreover, unlike diamond crystals, this material has a combination of order and disorder in its molecules. However, diamonds have highly organized and equidistant carbon molecules. According to the researchers, this might be the cause of its ‘superpowers.’ “The emergence of this type of ultrahard, ultrastrong, semiconducting amorphous material offers excellent candidates to most demanding practical applications,” noted the researchers.

Everything special about the ‘world’s hardest glass’

According to the researchers the glass has outstanding electronic and mechanical properties. In addition to this, its ultra-high strength and resistance to wear and tear make it a great contender for use in solar cells. After all, these are turnable energy absorption properties like those in semiconductors of solar cells and hydrogenated amorphous silicon films.

Furthermore, based on the analysis of AM-III as published in Oxford’s National Science Review, the material has a hardness of 113 gigapascals. Whereas, that of diamonds range between 50 to 70 gigapascals. “Consequently, our measurements demonstrate that the AM-III material is comparable in strength to diamond and superior to the other known strongest materials,” commented the researcher. However, it is a long road towards mass production.