Engineers at the University of Wisconsin-Madison have created a new technique that could bring commercial nuclear fusion reactors closer to reality. Nuclear fusion generates energy in the same way as our sun does. It entails slamming two atoms together with such power that they fuse into a single, bigger atom, releasing enormous amounts of energy in the process.

Unlike nuclear fission, which is currently used in the energy sector, fusion does not produce radioactive waste

Unlike nuclear fission, which is currently used in the energy sector, fusion does not produce radioactive waste. It produces three to four times more energy than fission and, unlike burning fossil fuels, does not emit carbon dioxide into the environment. Fusion is also an extremely fragile process that can fail in a fraction of a second if the proper circumstances are not met. As a result, there is no danger of nuclear meltdown from this reaction.

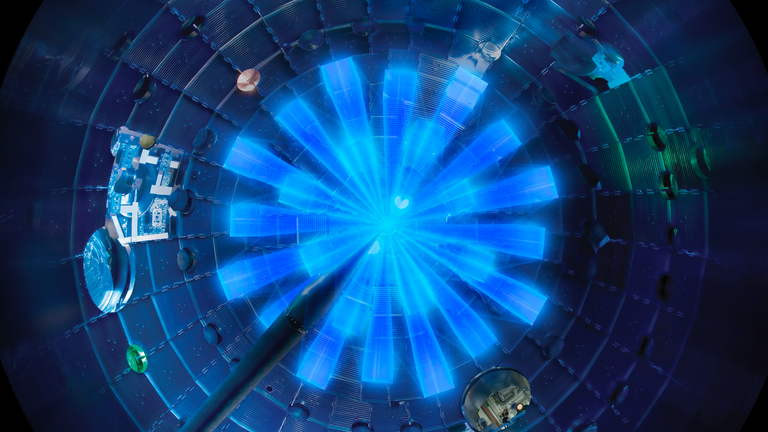

For this reaction to occur, we must be able to simulate circumstances similar to those found in the sun, which requires a significant amount of energy. For this reaction to occur on Earth, temperatures must be at least six times hotter than the sun’s core! At these extreme temperatures, atoms exist in a condition known as plasma, which is essentially a soup of negatively charged electrons and positively charged ions that have been blasted apart by their surroundings’ great heat. Most fusion reactors use hydrogen atoms for the process. When they are superheated, their single electron is pulled away, resulting in a soup of positive hydrogen ions and electrons. However, as the plasma cools, some of these hydrogen ions can attach back to the soup of electrons, producing neutralized hydrogen particles.

These neutralized particles can cause energy to be lost from the plasma, increasing the amount of energy required to maintain the reaction

So why is this a problem? These neutralized particles can cause energy to be lost from the plasma, increasing the amount of energy required to maintain the reaction. And for a process that is all about minimizing energy inputs, this is a major issue. “These hydrogen neutral particles cause power losses in the plasma, which makes it very challenging to sustain a hot plasma and have an effective small fusion reactor,” Mykola Ialovega, a postdoctoral researcher in nuclear engineering and engineering physics at UW–Madison, said in a statement.

To address this issue, the UW-Madison team developed a spray coating mechanism that can mop up these troublesome particles while also surviving the harsh temperatures within the nuclear reactor. “The fusion community is urgently looking for new manufacturing approaches to economically produce large plasma-facing components in fusion reactors,” she said. The team’s approach employs a cold spray process to deposit a coating of the metal tantalum on the reactor’s stainless steel surface. This metal can resist the reactor’s extremely high temperatures and is also excellent at absorbing hydrogen.

“With this research, we are the first to demonstrate the benefits of using cold spray coating technology for fusion applications.”

“We discovered that the cold spray tantalum coating absorbs much more hydrogen than bulk tantalum because of the unique microstructure of the coating,” Kumar Sridharan, a professor of nuclear engineering and engineering physics and materials science and engineering at UW-Madison, said in a statement. Cold spray technology is similar to spray painting using a can. It entails propelling particles of the coating material at a faster-than-sound velocity onto a surface. When they hit the reactor walls, they flatten out like squeezed M&Ms, forming a covering all over the surface. However, minor gaps exist between these particles, resulting in a higher surface area for hydrogen absorption. Even more interesting, when the material is heated further, the trapped hydrogen is released, allowing it to be recycled without changing the coating.

The coating is also easy to repair and replace, meaning it could not only make reactors more efficient but also easier to maintain. “Currently, damaged reactor components often need to be removed and replaced with a completely new part, which is costly and time-consuming,” Ialovega said. “Another big benefit of the cold spray method is that it allows us to repair reactor components on-site by applying a new coating.” “Our technology shows considerable improvements over current approaches. With this research, we are the first to demonstrate the benefits of using cold spray coating technology for fusion applications.”